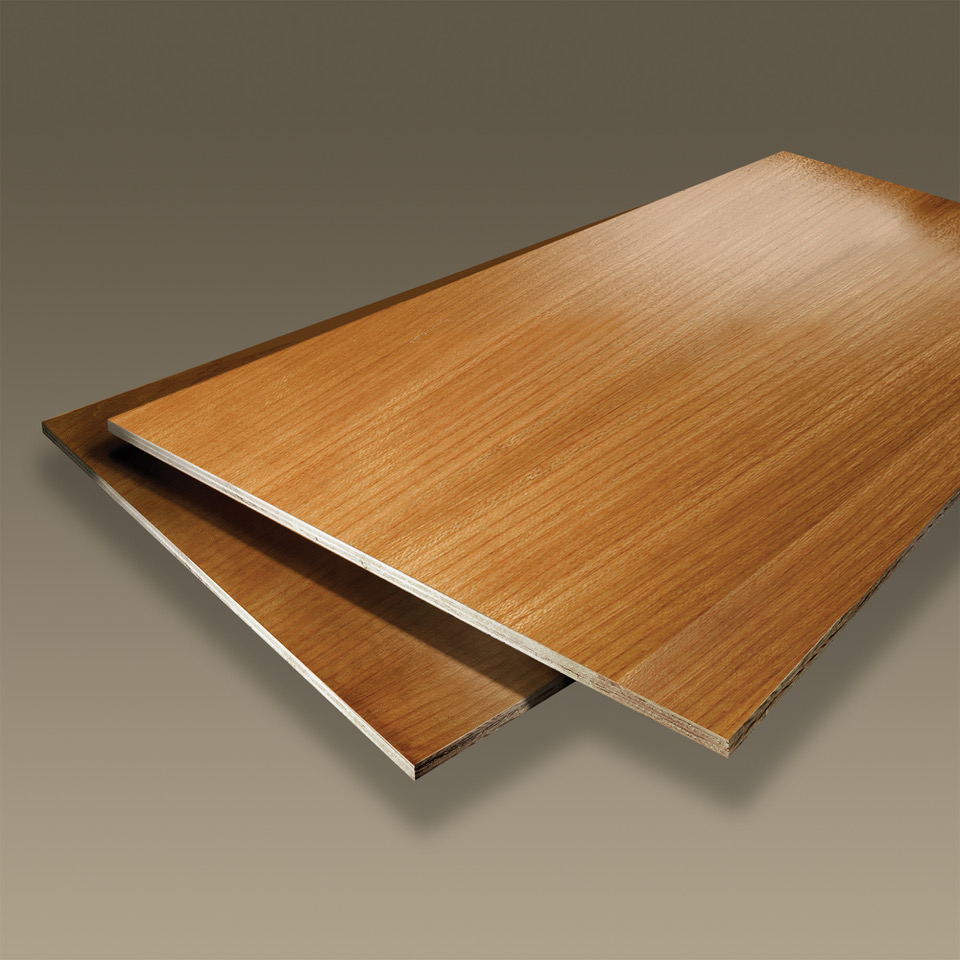

Hardwood Plywood

American Made Hardwood Plywood

Contact one of our knowledgeable sales people to ask about pricing and current availability of these wonderful panel products.

Spec Sheets

½” and ¾” VeneerCore plywood

½” and ¾” ArmorCore plywood

¼”, ½”, ¾” Appleply plywood

¼”, ½”, ¾” NOVA pre-finished VeneerCore plywood

We chose States Industries as our domestic plywood supplier because of their commitment to consistent high quality plywood panels.

How Do You Choose the Right Plywood?

Many factors determine the appearance and cost of decorative veneers used in States hardwood plywood panels. Being able to choose exactly the right combination to achieve the desired appearance is part of what makes hardwood plywood such a popular choice for designers, architects, craftsmen and other woodworking professionals.

STEP 1

Choose the Substrate

The process of creating your custom hardwood paneling starts with choosing the core (substrate) of your panel. Core selection is often a balancing act of choosing between performance characteristics and price.

What types of plywood cores are available?

Veneer core is comprised of wood veneers laminated in alternating directions to achieve the desired panel thickness. Veneer core panels can be laminated in one step for maximum economy or constructed and sanded to a metered tolerance using a two-step laminating process.

Combination core is a hybrid substrate, combining composite crossbands with veneer innerplies to produce an exceptionally flat, smooth surface. These panels can be used when there is a need to have the weight, structural value and screw-holding ability of veneer core with the flatness and higher density of MDF.

Composite core is made by combining composite crossbands with veneer innerplies to produce an exceptionally flat, smooth surface. They’re valued for their flat, smooth surfaces and tight tolerances, as well as their relatively low costs.

STEP 2

Choose the Front and Back Veneers

Once you’ve chosen a substrate for your panel, the next step is to decide what veneers will cover the front and back of the panel. Choices to consider include the wood species, what type of cut, how the veneers are matched and what grade fits your project.

STEP 3

Choose Thickness and Length

We stock most items in a standard sized panel 4 x 8 sheet. Custom orders can be ordered and can include custom panel thickness, as well as extra short or extra long panel lengths.

STEP 4

Choose a Finish or Not

The final step in choosing your plywood panel is to determine whether you need a finished or unfinished panel. A wide range of options are available in both unfinished as well as UV-cured. States Industries offers their flatline finish NOVA line, anti-microbial NOVA SI, laboratory-grade NOVA LAB finish, popular NOVA Peak options or completely custom color matching for whatever you need.

Wood Species Guide

Natural woods vary in performance characteristics from one another. This wood comparison chart helps you compare hardness, weight, fungal resistance, and more. Use the wood comparison guide to help you find the right wood for your project.

Locations

Locations are strategically placed throughout the United States to serve our customers. Products stocked at each location are different based on customer needs.